Libraries, requirements and testing are just a few areas to get started with AI in engineering.

Design engineers number in the hundreds of thousands, if not millions, worldwide. That represents a massive pool of valuable knowledge—industry-specific processes, personal workflows, procedures and more—that could be leveraged through machine learning.

From my own experience as a design engineer, it was clear even then that parts of the job were repetitive and could be improved or automated. One traditional approach was to build up component libraries. However, these libraries were often specific to a plant or product line, and even within the same company, different teams had their own isolated systems.

Some experienced engineers had developed individual shortcuts or retained knowledge from repeated exposure to the design–rework–release cycle. While effective, this knowledge was often locked in the minds of a few senior engineers. If one of them left the company or chose not to share their methods, that expertise became difficult or impossible to scale across teams or locations.

This raises an important question: How can we reduce knowledge silos and make engineering know-how more accessible?

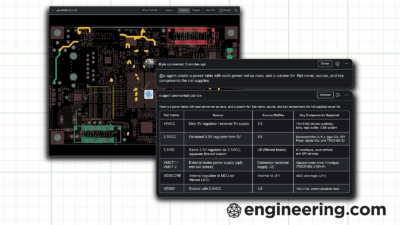

One answer is to use an AI agent—not to replace the engineer, but to assist them. An AI-powered digital assistant could speed up decision-making and help engineers understand the reasoning behind choices.

Take the automotive industry, for example. Consider the screw used to mount a headlight in a Ford Focus. It might be an M6x18mm screw—but why that specific part? The choice may involve testing data, torque specs, material considerations, weight limits, or economic factors. All of this information exists and could be made accessible to a machine-learning model to assist engineers during the design phase. If integrated with a CAD tool, the AI agent could suggest appropriate components based on context and past data.

This concept can scale beyond automotive. With access to industry-specific libraries, an AI assistant could help engineers find relevant solutions quickly. It wouldn’t replace human insight but would reduce time spent on repetitive tasks—like browsing through component catalogs—and allow engineers to focus on creative problem-solving.

Companies often sit on vast datalakes of underused information. Training AI models on this data could improve efficiency and reduce costs. Consider a test engineer working in a lab: an AI agent could analyze past test results to flag potential points of failure in new assemblies, improving comparative analysis and cutting down on wasted manufacturing costs.

Other applications include:

- Suggesting library components to reduce design time.

- Recommending material thicknesses at the component level.

- Providing context to help junior engineers understand the “why” behind a design decision.

Ultimately, AI agents aren’t here to replace people. They’re tools that, when used wisely, can foster both personal and organizational growth. The future isn’t man versus machine. It’s about using these tools to create a partnership where the human factor—context, ethics, judgment—drives the machine to be more useful.

AI can sift, learn and adapt. But it’s the engineer who decides what matters.