VI-grade’s advanced driving simulators and cloud-based data solutions enable engineers to shift from traditional sequential development cycles to more agile approaches that reduce costs and time.

We’ve been covering the “zero prototypes” design philosophy lately and following the VI-grade team’s progress on their journey, which they don’t trek alone. The company has numerous partnerships and nurtures an ecosystem of global stakeholders necessary to drive this ambitious effort.

On June 12, 2025, VI-grade hosted the North American Zero Prototypes Day at its SimCenter in Novi, Michigan, located within Multimatic’s facility. This day piggybacked on the company’s international Zero Prototypes Summit event in Udine, Italy, held in May. Videos of each presentation are available online, but here are some key takeaways from experts and exclusive interviews.

Virtual and physical testing are two sides of the same coin

“It’s quite clear that the industry is moving at a rapid pace towards virtualization,” said Omar Elsewify, chassis development engineer (Vehicle Dynamics) at Hitachi Astemo. “OEMs are pushing more and more for their suppliers to match their agility in terms of virtual capabilities. More and more, we’re seeing OEMs ask their suppliers to be involved in the validation and integration stage, as well as virtually developing and virtually validating. As those virtual requirements have increased for validation, so have the testing requirements, and what used to be acceptable in terms of just providing software-in-the-loop validation has now increased the requirements to provide hardware-in-the-loop capabilities, driver-in-the-loop capabilities, as well as vehicle-in-the-loop capabilities, in some cases.”

Astemo developed a high-fidelity AI-MBD damper model as a software-in-the-loop solution that runs in real time and captures real-world dynamics. The company uses VI-grade’s Full Spectrum Simulator (FSS) to validate the model with hardware-in-the-loop and driver-in-the-loop simulations.

“The damper for them is real, because in the end, they have to come up with a real product. But very often, they don’t have a real car, so they use a virtual vehicle model and perform an auto-in-the-loop simulation, in which you have the damper in the loop with everything else,” said Guido Bairati, VP of global sales at HBK (VI-grade’s parent company) and former managing director at VI-grade. “The driving simulator has the great advantage of putting the driver in the loop into the equation, so you can easily test your component with a real driver.”

Simulators are game-changing for design and development cycles, helping engineers test everything from components and powertrains to human-machine interfaces (HMIs), driver comfort, and more. David Trumpy, senior principal software engineer at Harmon Becker Automotive Solutions, discussed how his team integrates their sound design library in a VI-grade noise, vibration, and harshness (NVH) simulator, which stakeholders use to evaluate and provide feedback for future iterations.

“The simulator is sending the control data over to our library, and we send the audio samples back, so it’s added in just like another layer or another sound component. We find that the desktop simulator enables our team to manage multiple configurations, so they can switch between different versions, different software releases by using different sound objects,” said Trumpy. “We can share these sounds across team members. We have team members around the globe working on sound design and feature development, and then we can test over a wide array of use cases, like fixed driving modes. In the fixed driving mode, we can use playback from a recorded vehicle, and in free driving mode, we can interact with the vehicle like a driver in the loop. We can also live-tune our algorithms while we’re running in the simulator. So we can connect our tuning tool directly to our algorithm while it’s running and change parameters and hear the difference live in real time.”

Trumpy admitted that they aren’t ready to give up their test vehicles due to differences between the simulator setup and vehicle testing. He noted that data in the simulator can be overly idealistic, so high-fidelity powertrain models are essential for tuning algorithms, as well as testing a wide range of driving scenarios.

Though the goal of zero prototypes is to produce a first car that can be sold and driven off the lot, Bairati reminds us that virtual testing and physical testing are two sides of the same coin. Yet, virtual testing technologies go beyond cool features and cost savings and now ensure survival in this increasingly competitive global market that pushes companies toward virtualization.

“The industry is seriously pursuing zero prototypes to reduce costs and delays, with companies aiming for 100% virtual development,” said Bairati. “This urgency is particularly pronounced in China, where rapid development cycles are becoming the norm. They are talking about developing a car in 12 to 18 months. If you want to really develop a car in one year, there is no way but virtual.”

This technological evolution is fundamentally changing how engineers work, shifting from the traditional sequential V-cycle process to more iterative approaches.

“We are moving from a sequential type of development to more parallel development, enabled by continuous testing loops that provide faster feedback and more agile development cycles,” said Bairati. “Physical testing will not disappear, but it will change, and it will be used to create better virtual models. And then the virtual models will be used to optimize the physical test that you have to do at the end of a development cycle.”

Advanced simulators help speed up development

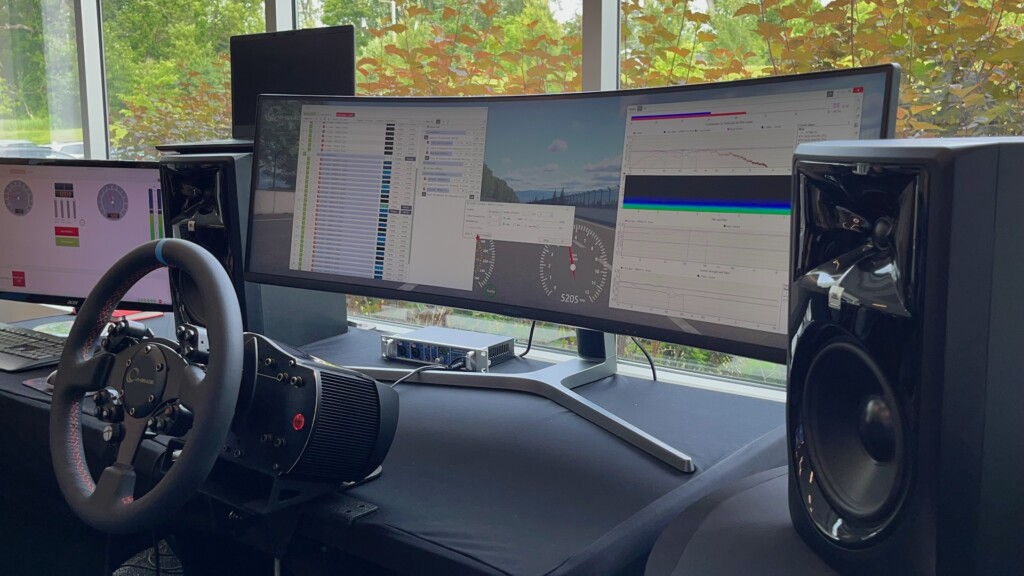

Admittedly, using a vehicle simulator is a fun experience, but the technology is significantly more advanced than any arcade game and is designed to collect specific, real-time data for engineers to improve and innovate.

“Our mission is to help you win the zero prototypes challenge, to help you innovate faster. And we do that through a combination of driving simulators, simulation software, and HiL systems,” said Dave Bogema, senior director of product management at VI-grade.

Two years ago, VI-grade announced its Compact FSS, which combines vehicle dynamics and NVH in one simulator. Last year, the company took another step forward by launching its Driver-in-Motion Full Spectrum Simulator (DiM FSS), which provides six degrees of freedom for a highly immersive experience, allowing engineers to evaluate several vehicle attributes simultaneously.

“Over the last 10 years, we have been developing simulators with higher peak accelerations, lower latency, and improved dynamics overall. This year, we’re announcing the next step in that evolution, the HexaRev,” said Bogema. “It’s a six-degree-of-freedom motion platform unlike any other.”

The design is simple, with six motors connected directly to the cockpit. There are no ball screws, gears, belts, chains or anything that could create extra noise or vibration. The system is quiet and provides an immediate response.

“When you have a traditional six-degree-of-freedom system, as you have multiple degrees of freedom active at the same time, your overall motion envelope kind of shrinks,” said Bogema. “The HexaRev maintains a much larger overall motion envelope, so it gives you a much bigger dynamic space to work with. If you combine the HexaRev with the Hyperdock, which is our carbon fiber cockpit that we launched last year, this turns it into an FSS simulator, able to simulate that whole range from zero to 20 kilohertz.”

This year, VI-grade also launched the Compact HMI, a highly configurable simulator that can switch between multiple cockpit configurations using a touchpad. It also serves as a real-time driving simulator, allowing the vehicle to be tested in various environments and scenarios, and to evaluate HMI concepts.

“When you’re evaluating HMI concepts, you really need the driver in the loop, because at the end of the day, it’s the driver who decides whether that HMI is good enough,” said Bogema.

Prioritizing humans in an AI-driven future

As vehicle design becomes increasingly complex, and engineers must design, develop, and test faster, VI-grade launched VI-DataDrive Cloud to help engineers extract insights from data quickly.

“VI-DataDrive Cloud is focused on VI-CarRealTime. If you look at how we normally use VI-CarRealTime, you would sit at a workstation, build your models, design your tests, run those simulations at your local workstation, and then analyze the results again at that local workstation,” said Bogema. “What we’re doing here is changing that paradigm, still allowing you to design the test at your local workstation, but then upload to the cloud and run lots of simulations in parallel. What this enables you to do is process a lot more data.”

The solution also enables engineers to share data rapidly, collaborate more effectively, and make decisions faster. As Bairati mentioned, making sense of data is key for iterative development.

“Primarily, what I see is customers struggling with a large amount of data. All customers are telling us that generating data is not an issue. They actually generate from a virtual and physical test more data than they are able to manage,” he said. “The issue they have is how to make that data available within the organization and to look into the data. In the near future, there will be AI agents who are looking into data and telling engineers in which direction to go for the next development step.”

Bairati also said the ultimate goal is to create digital twins that can be continuously updated with real-world fleet data. And though AI isn’t yet widely used, it’s emerging rapidly and will eventually become ubiquitous in the virtual testing and vehicle development process.

However, AI won’t usurp human jobs and expertise. In fact, Iain Dodds, VI-grade’s technical director in North America, cautions against unchecked reliance on AI and even reliance on people who lack domain knowledge.

“You get people who don’t understand the domain coming in and just take it from a pure data perspective. And that gets scary,” said Dodds. “You’ve got to make sure the conclusions you get from your data are valuable and relevant, and not just data for data’s sake.”

Dodds demonstrated the VI-WorldSim graphics environment and explained how the product has matured, yet they’re just scratching the surface of its capabilities.

“WorldSim can create a graphics data feed from a sensor. It can simulate a sensor, camera, radar, LiDAR, and the quality of the data coming out can actually be used to do ADAS development,” he said.

Engineers can use WorldSim for data generation and algorithm validation, and can even integrate hardware components into the simulation. “The simulation is getting that good,” Dodds said, yet the technology adoption requires trust in the model and trust in the people developing the algorithms. Greg Stevens, research director of Mcity at the University of Michigan, addressed this during his presentation on “the curse of rarity.”

“If you have an autonomous vehicle, today it’s basically being driven with AI algorithms, and AI algorithms are really good at handling situations that they’ve seen before. They’re not really great right now at adapting to novelty, to situations they haven’t seen before,” said Stevens. “That’s where the curse of rarity comes in because the goal is to get enough training data to train your AI algorithm properly.”

Normal driving data is a dime a dozen. Engineers can collect data at any time of day or night to capture normal conditions. As Stevens noted, the challenge is “the safety-critical and near-miss data.” Accidents, especially fatal accidents, are considered rare, which makes it difficult to simulate physically.

“It just doesn’t scale. Simulation has to be part of the solution here,” he said.

Next steps on the zero prototypes journey

In addition to AI advancements and faster, more interactive design and development cycles, Bairati emphasized the growing importance of multi-attribute simulation for virtual testing and vehicle development.

“Historically, there were simulators for different disciplines. Think about Formula One. They only care about vehicle dynamics. They only care about lap time. They don’t care if a car is noisy or not,” Bairati said. “But customers are asking us for simulators that are able to study how the car handles, how the car rides, and how the car sounds, or the tire, not just the car, but also components at the same time. Because when you drive your car, you experience all these different attributes together simultaneously. You care about how the car handles on a winding road, but at the same time, you also enjoy if a car is silent and how it rides. So, we at VI-grade put a lot of effort in the last three to four years to have a multi-attribute simulator where you can study all different disciplines.”

To move such advanced technology forward, partnerships will continue to be a priority, such as that of VI-grade and Multimatic.

“Our relationship with VI-grade dates back decades,” said Peter Gibbons, technical director of vehicle dynamics at Multimatic. “Fifteen years ago, we commissioned the first viable simulator for vehicle development, and that happened in Toronto. From then on, it’s continued to the point of doing this cooperative relationship here, where basically VI-grade and Multimatic are joined as one for this facility.”

John Kipf, engineering director of operations at Multimatic, added that the partnership has many successful years ahead.

“We’ll continue to grow, particularly as we do a lot of ride-based things within the vehicle dynamics sphere, it’s an opportunity for us to explore and do more in that,” Kipf said. “That’s really how this place came to be. It’s been really good, and we support each other as much as possible.”

To learn more about VI-grade and Multimatic’s SimCenter Detroit, visit

vi-grade.com/en/services/simcenters/simcenter_detroit.