With DELMIA, manufacturers are moving beyond disconnected tools to reduce waste, improve throughput, and respond faster to change.

GoEngineer has sponsored this post.

You’re likely feeling pressure from every direction right now. Customers increasingly expect mass customization, which means you’re being pushed to deliver more personalized products, faster. And if you’re in a fast-paced industry like consumer electronics, you’re also under pressure to keep up with shrinking development cycles, where companies are setting the standard with yearly product launches.

At the same time, you’re navigating serious internal challenges. Volatility in the price of core components like steel and semiconductors is squeezing margins and making it harder to plan. And even when you can source materials, finding and keeping skilled labor is a constant battle. You’re likely balancing investments in automation, process optimization, and workforce upskilling—just to keep production moving.

All of this is unfolding against a backdrop of global instability, from supply chain disruptions to inflation and rising interest rates. Staying competitive now requires real control and visibility across your operations. But if you’re still relying on disconnected systems—ERP, spreadsheets, paper, or a patchwork of point solutions—it’s going to be nearly impossible to achieve the outcomes you’re being asked to deliver.

“With current geopolitical events, it’s becoming increasingly necessary for manufacturers to integrate their supply chain with their manufacturing so they can better react to market conditions and new regulations,” says Niranjan Kalele, Director of MES and APS Engineering at GoEngineer.

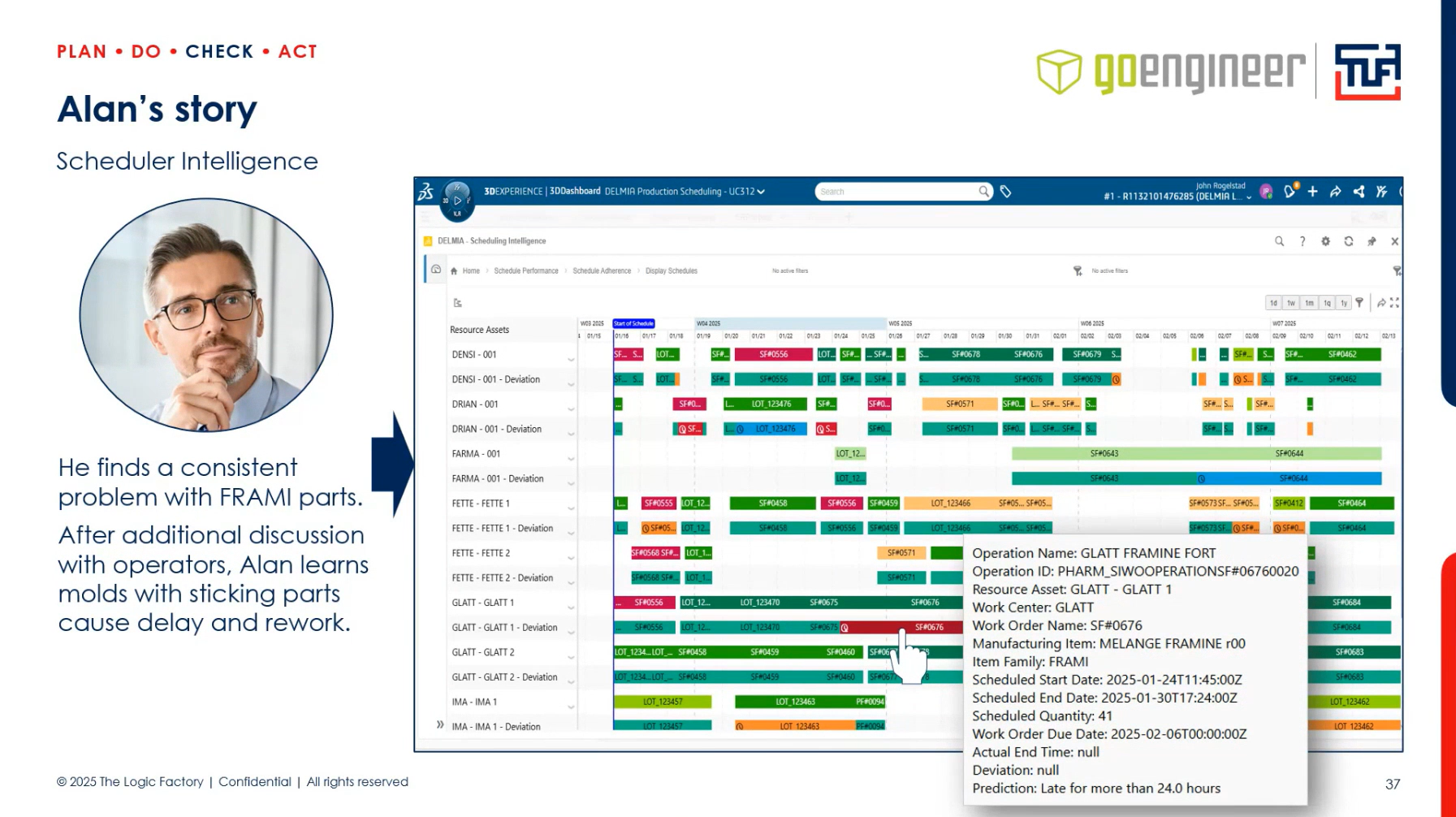

The challenges are even more difficult to manage when planning and execution operate in silos. Traditional planning systems assume infinite capacity and don’t take into account real-world constraints—such as a machine being down, or material shortages—often rendering the plan unachievable by the time it reaches the floor.

“Not having planning aligned with execution causes chaos in trying to meet production orders and schedules, especially when coordinating across multiple plants and geographies,” says Darren Kline, Director of Manufacturing Solutions for GoEngineer.

To stay flexible and cost-effective within this kind of environment, manufacturers need a unified solution. DELMIA offers an integrated approach that connects planning, scheduling and execution within a single system.

The problem with disconnected tools

For many manufacturers, planning still happens in the comfort zone of familiar tools such as Excel and ERP systems. However, this means building a custom scheduling and optimization tool from the ground up.

“You’re essentially recreating something that already exists on the market, and that tool is completely disconnected from what’s actually happening around your plant,” says Kline. “When things change, your model has to be manually updated, so you’re constantly behind in visibility.”

“Most ERP planning systems generate orders based on demand and push them to the shop floor regardless of whether it’s actually capable of manufacturing those quantities or meeting the deadlines,” adds Kalele. “You need a way to optimize without incurring extra costs like overtime or outsourcing, while still trying to meet demand. Creating that optimal schedule is often beyond human comprehension and requires specialized software.”

The DELMIA solution

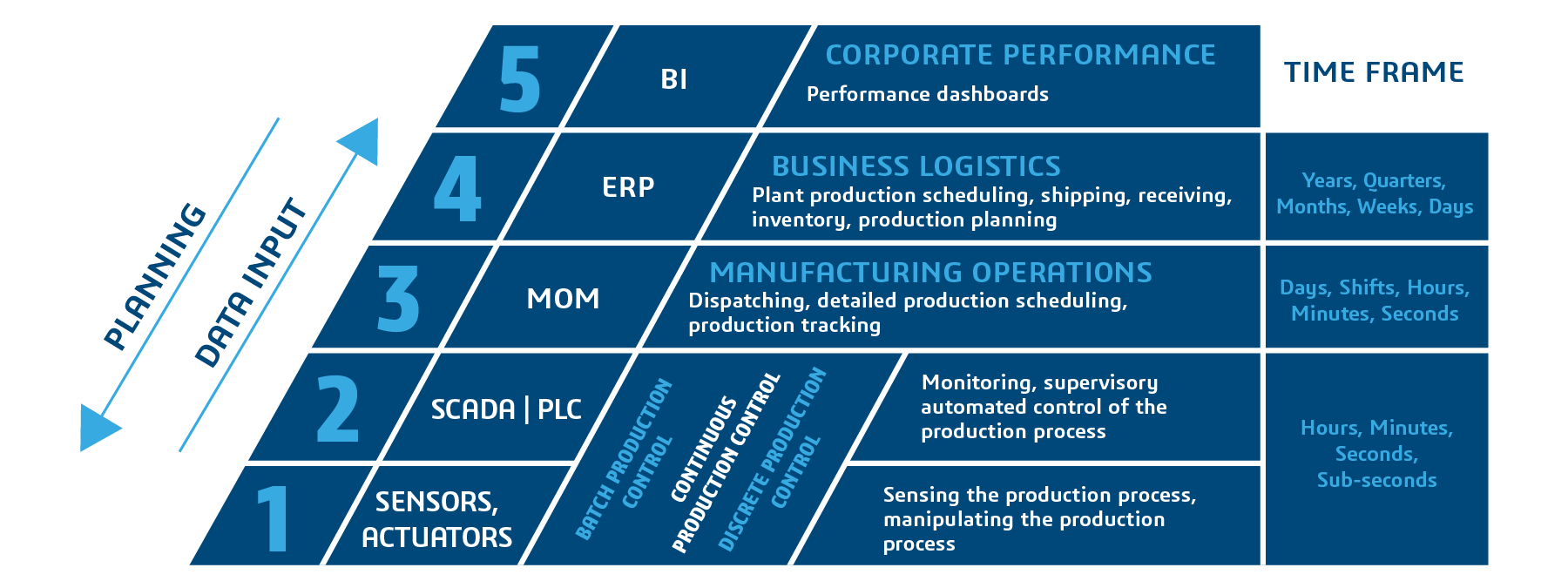

DELMIA, part of the Dassault Systèmes portfolio, addresses these issues by reacting to real-time events on the shop floor. Two of its core scheduling products—Ortems and Quintiq—work at different levels to provide a more responsive view of manufacturing operations.

Ortems functions at the plant level to build production schedules based on constraints such as labor availability, material supply, and machine capacity. Teams can run what-if scenarios to come up with the best achievable schedule, which can then be pushed to ERP systems and pulled into MES for execution.

Quintiq operates at a broader, interplant level. “If you have an internal supply chain, where one facility produces products that become raw materials for the next, Quintiq helps optimize the entire production schedule across facilities so no plant is left waiting for materials,” says Kalele.

“It also handles multi-year sales and operations planning and logistics planning—managing and optimizing shipments across networks, whether by train, boat, or other methods,” adds Kline.

On the execution side, DELMIA Apriso serves as a Manufacturing Operations Management (MOM) platform. It touches all the operations on the plant floor, from receiving raw materials to shipping finished goods—with these activities residing on a single database through a unified data model. Users can configure business rules with Apriso’s built-in Process Builder tool.

Apriso extends beyond traditional MES functions by encompassing five components: production execution, quality management, warehouse and materials management, maintenance management, and time and labor management. “Customers can pick and choose which components to begin with,” says Kline. “It can start at a single-plant level and scale up to support global operations. Its Center of Excellence environment allows you to build a manufacturing operations template, deploy it across all locations, and tweak those templates for the unique aspects of each operation, while still managing everything centrally. That’s the best of both worlds.”

What distinguishes DELMIA from other platforms is its integration with Dassault Systèmes’ 3DEXPERIENCE environment. By sharing a common data model, DELMIA enables a natural flow of information and closed-loop operations across product engineering, manufacturing planning, and execution—allowing manufacturers to easily react to changes.

“If an engineering change is initiated based on a shop floor experience, that change can flow through the entire process—from engineering to manufacturing engineering and back to the shop floor—in a seamless way,” explains Kalele. “This digital continuity sets DELMIA apart in the marketplace.”

The benefits of a connected system like DELMIA show up in measurable ways. On the planning side, manufacturers report improvements in on-time delivery, throughput, and lead times. Inventory levels are easier to manage, and planners save hours by running optimized scenarios that would otherwise take a full day in spreadsheets.

From the MOM standpoint, Apriso helps reduce scrap, rework, and work-in-progress by ensuring operators have up-to-date instructions and only see tasks they’re qualified to perform. The system also cuts paper use significantly and streamlines the process of onboarding new operations.

“With DELMIA, you gain instant visibility into plant floor operations,” says Kline. “Once you can measure what’s happening, the system enables you to build improvements into your operational processes—so the next time you execute, you’re doing so with updated best practices. It becomes a platform for continuous improvement.”

Watch GoEngineer’s on-demand webinar for an in-depth introduction to modern production planning, beyond Excel and ERP.

To learn more, visit goengineer.com.