By Emily Williams, Content Writer & DAM Librarian

In February 2025, President Trump announced a sweeping 25% tariff on steel and aluminum imports, closing loopholes previously used by global suppliers. A month later, a similar tariff hit automobiles and automotive parts. And while the political landscape may shift again tomorrow, one thing remains constant: the impact on manufacturers is immediate, and often painful.

Tariffs might be long-game political strategy—but for engineers and manufacturers, they hit the bottom line, complicate sourcing, and create uncertainty. Large companies like Honda, Johnson & Johnson, and Nvidia have already responded by investing more heavily in U.S.-based production. But for small to mid-sized manufacturers, these changes often mean layoffs, shrinking margins, or passed-on costs.

So how can North American manufacturers respond in the short term while staying resilient in the long term? Here are three practical strategies to consider:

1. Reimagine Materials: Use Carbon Fiber Instead of Aluminum or Steel

Ask yourself: Does your part really need aluminum? Unless you’re building aircraft or beverage cans, the answer might be no.

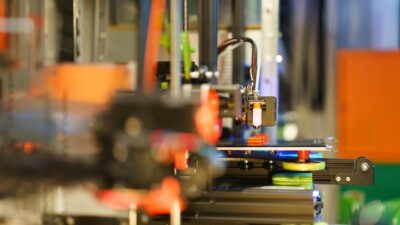

Reinforced carbon fiber is an excellent alternative that combines high strength, low weight, and corrosion resistance. With solutions like Markforged’s FX10 and FX20 3D printers, you can produce components with strength on par with 6061-T6 aluminum—minus the tariff markup.

These printers use a composite base (Onyx or Onyx FR) and layer in continuous carbon fiber, creating durable parts ideal for:

- Robotic arm attachments

- Telescopic components

- Outdoor gear like tent poles

- Aerospace and drone components

Bonus: Markforged is a U.S.-based supplier. That means lower emissions from shipping, faster lead times, and support for American jobs.

Note: Carbon fiber isn’t a fit for everything. Applications requiring thermal or electrical conductivity—like heat sinks—still belong to aluminum. But for many structural applications, reinforced composites are a game-changer.

2. Embrace MaaS: Manufacturing-as-a-Service

Need parts fast? Working with a local MaaS provider could be the key to staying agile and affordable in a turbulent market.

Manufacturing-as-a-Service (MaaS) platforms allow you to outsource production on-demand to vetted shops across North America. Whether you need CNC machining, 3D printing, or inspection services, MaaS delivers benefits like:

- Flexibility: Scale up or down depending on demand

- Speed: Reduced lead times by working with local providers

- Sustainability: Lower carbon emissions from minimized shipping

- Expertise: Consultative advice on the right materials, processes, and tools

At Hawk Ridge Systems, we offer on-demand access to trusted manufacturing partners across North America, plus deep expertise in software, additive manufacturing, and design optimization.

3. Rethink Your Supplier Network: Commit to “Made in America”

Global supply chains used to be about saving a few bucks. Now, the risk often outweighs the reward.

If you’re evaluating vendors, ask yourself:

- Are they based in North America?

- Where do they source their raw materials?

- Are their operations transparent and traceable?

- Do they align with your customers’ values?

Choosing U.S.-based suppliers improves part traceability, cuts down on transportation emissions, and meets consumer demand for American-made goods. Plus, working with local partners fosters resilience—something global shipping lanes and international politics can’t promise.

Why Manufacturers Partner with Hawk Ridge Systems

Navigating these shifts isn’t easy, but you don’t have to go it alone. Hawk Ridge Systems helps thousands of engineering and manufacturing companies stay competitive, agile, and future-ready.

Here’s why so many choose us:

- We’re North America’s largest SOLIDWORKS training provider with flexible options to upskill your team.

- We have 20+ offices and 400+ employees across the U.S. and Canada, providing deep local coverage.

- We offer 12-hour support windows for tech issues, design help, and troubleshooting—when you need it most.

This Won’t Be the Last Tariff Change… But It Doesn’t Have to Be the End of Profitability

Tariffs, shifting trade policies, and economic uncertainty are part of today’s manufacturing reality. Whether or not TikTok gets sold or the next round of tariffs hits your sector, adapting your sourcing and production strategies now will give you a critical advantage.

American manufacturing isn’t just coming back—it’s evolving. And Hawk Ridge Systems is here to help you evolve with it.

Ready to evolve? Contact us today.