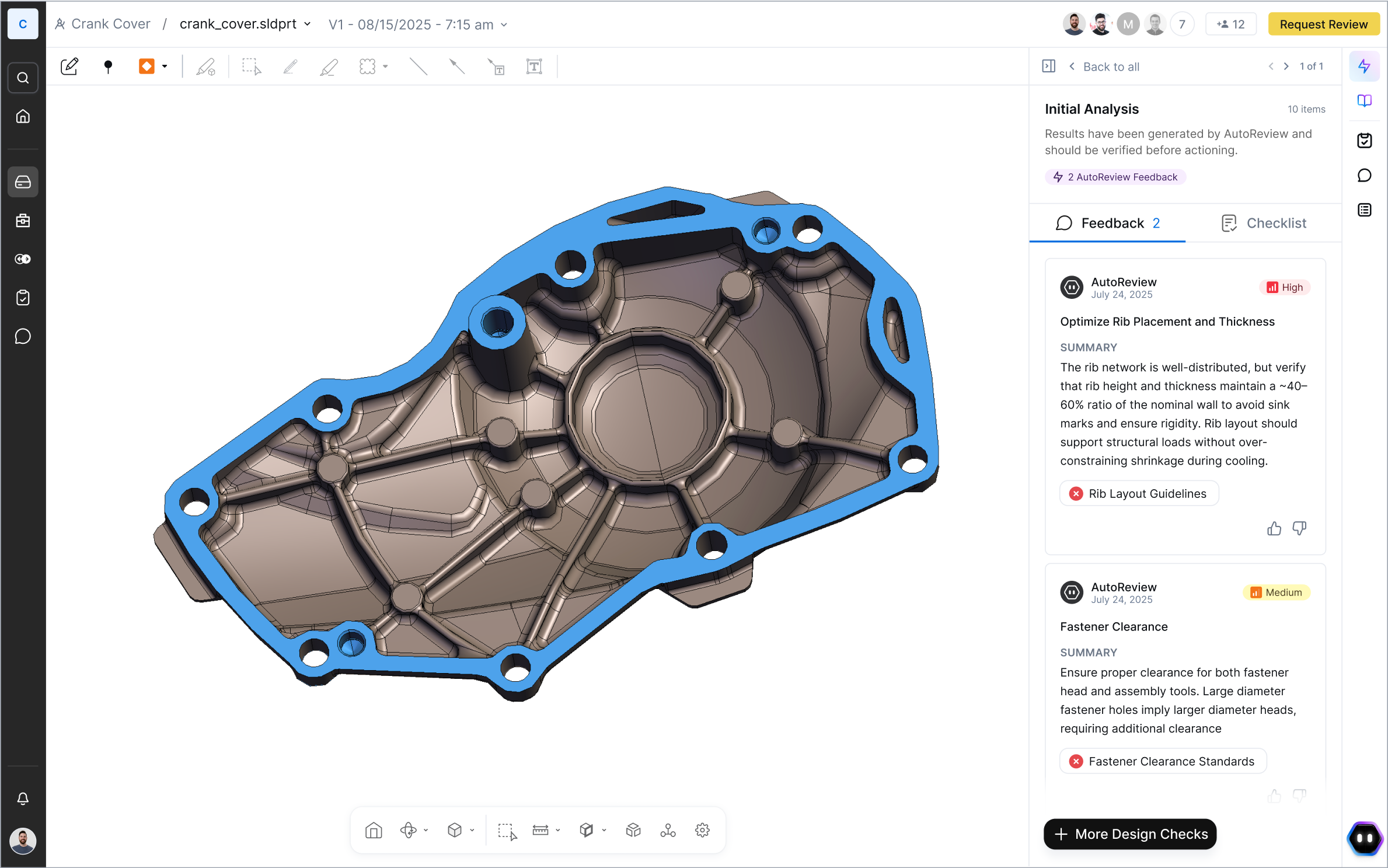

AutoReview scans documents to identify common issues, including drawing errors and design for manufacturing concerns.

CoLab, a technology company focused on improving engineering design reviews, has released its new AI tool, AutoReview, six months earlier than planned. AutoReview is an enterprise-oriented system that automatically reviews 2D drawings and 3D models. The early release follows faster-than-expected progress by CoLab’s product and engineering teams. The tool is intended to support productivity, quality control, and error reduction in design workflows.

The tool is currently being tested in beta by manufacturers including Techtronic Industries (TTI), the parent company of RYOBI, and wind turbine blade manufacturer TPI Composites. Both companies are evaluating its ability to identify design issues early and support more consistent review processes.

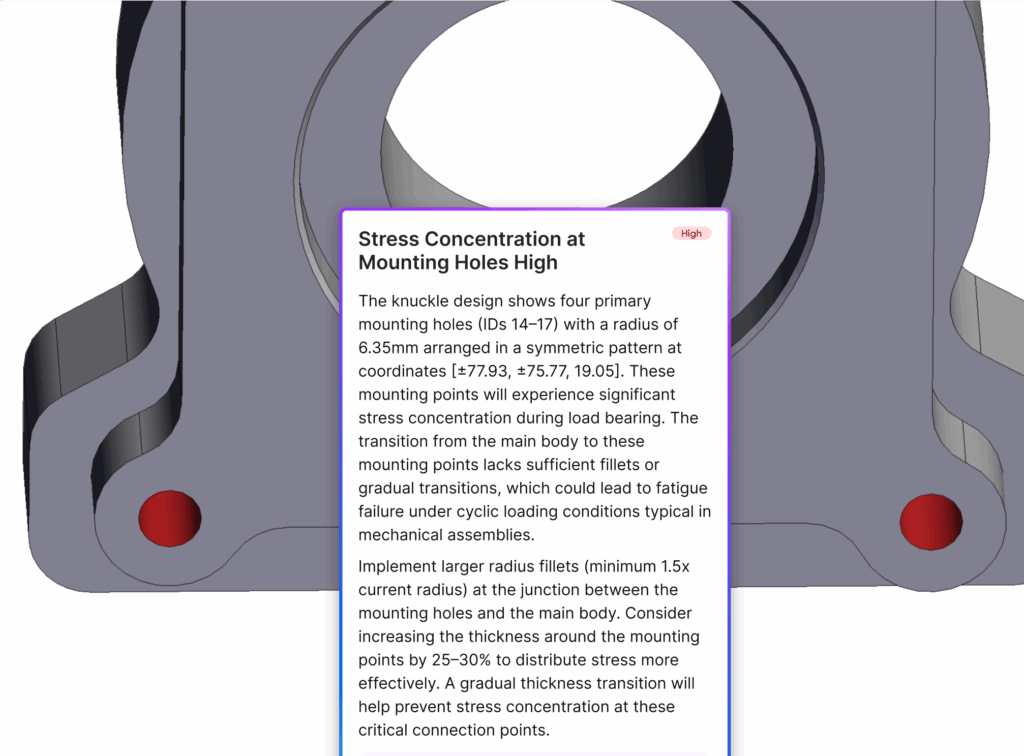

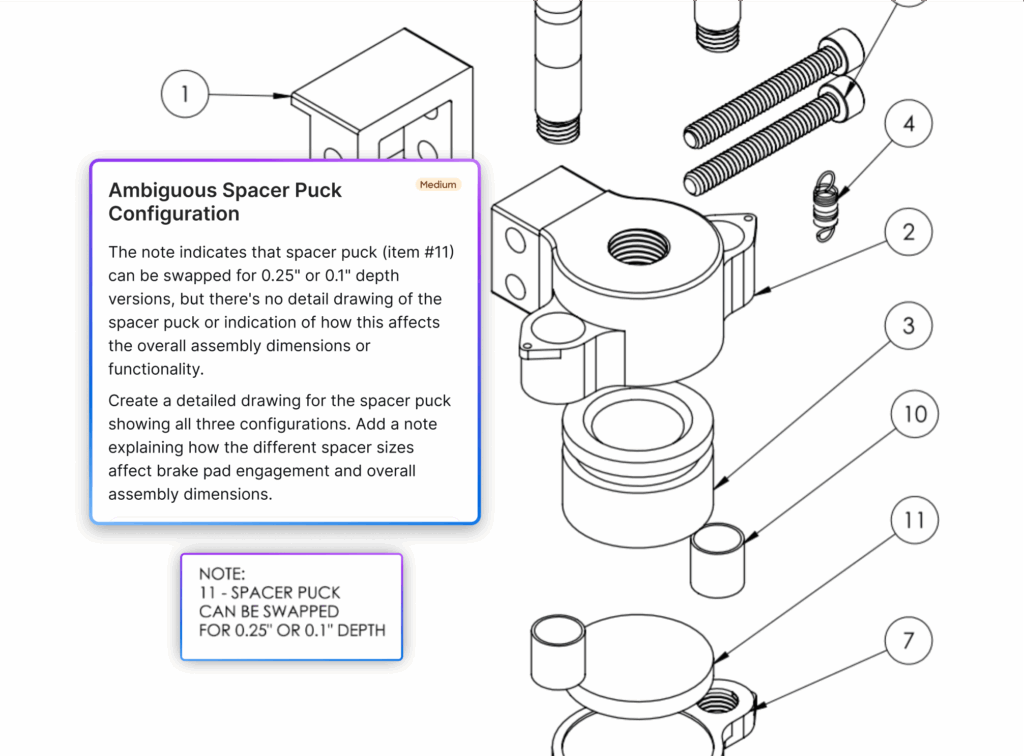

AutoReview scans documents to identify common issues, such as errors in drawings and design for manufacturing (DFM) considerations. For instance, it can detect missing or incorrect countersinks—features that help ensure a screw head fits properly. It also checks molding measurements to verify wall thickness and assess whether molds can be removed effectively during manufacturing.

The software can also automatically surface lessons learned from past programs during reviews of in-work designs that use similar geometry or the same parts, helping avoid costly mistakes being replicated across different designs. This can create significant savings by reducing scrap rates and warranty claims. In 2024, the US car and cycles industry alone paid over $12 billion in warranty claims, a 17% increase from 2023 according to Warranty Week.

In complex manufacturing industries such as aerospace and MedTech, missing one dimensional check can mean reworking a drawing or delaying a critical product milestone. AutoReview can replace redundant manual checks and deliver greater consistency and adherence to company-specific design rules by validating 2D drawings and 3D models across different programmes including Creo, NX, SolidWorks and CATIA.

Beyond adherence to standards, AutoReview can also automatically identify design for manufacturing (DFM) optimizations. This capability has caught the attention of automotive OEMs and tier 1 suppliers, who see an opportunity to reduce scrap, prototyping, and tooling costs.

The solution also ensures design IP is protected across manufacturing sectors, as AutoReview runs inside CoLab’s secure environment and works with existing PLM infrastructure. This means teams can move files into review without taking them out of their governed systems.

CoLab’s core Design Engagement System (DES) is already delivering measurable results for engineering teams at Schaeffler, Johnson Controls and Mainspring Energy. These teams have cut BOM costs by up to 50% and accelerated design cycles by 100%, launching products months earlier.

For more information, visit colabsoftware.com.